In the realm of manufacturing, precision and durability are paramount. Stainless steel metal strips have emerged as indispensable components across various industries due to their exceptional properties. At Jianglinsteel, we specialize in producing high-quality stainless steel strips tailored to meet diverse industrial needs.

What Are Stainless Steel Metal Strips?

Stainless steel metal strips are thin, flat pieces of stainless steel that undergo processes like cold rolling and annealing to achieve desired thicknesses and mechanical properties. These strips are characterized by their resistance to corrosion, high strength, and versatility, making them suitable for a wide range of applications.

Key Properties of Stainless Steel Strips

1. Corrosion Resistance

One of the standout features of stainless steel is its ability to resist corrosion. The formation of a passive oxide layer on the surface protects the material from rust and staining, ensuring longevity even in harsh environments

2. High Strength and Durability

Stainless steel strips possess impressive tensile strength, allowing them to withstand mechanical stresses and impacts without deformation. This durability ensures that components made from these strips have a prolonged service life.

3. Excellent Formability

Despite their strength, stainless steel strips are highly formable. They can be easily bent, stamped, or welded into various shapes, making them adaptable to complex designs and specifications.

4. Aesthetic Appeal

The smooth, shiny surface of stainless steel strips adds a modern and sleek appearance to products. This aesthetic quality is particularly valued in consumer-facing applications where visual appeal is crucial.

Applications Across Industries

1. Automotive Industry

In the automotive sector, stainless steel strips are utilized for manufacturing components such as exhaust systems, clamps, and brackets. Their resistance to corrosion ensures that parts exposed to harsh environmental conditions remain intact for extended periods.

2. Construction and Architecture

Stainless steel strips play a crucial role in construction and architecture due to their strength, durability, and visual appeal. They are used in roofing, structural beams, window frames, and decorative cladding. The material’s ability to resist weathering makes it ideal for both indoor and outdoor applications.

3. Medical Equipment

In the medical field, hygiene and safety are paramount, and stainless steel’s non-porous surface makes it easy to clean and sanitize. Stainless steel strips are used in the manufacture of surgical instruments, dental equipment, and even in the production of implantable medical devices.

4. Electronics Industry

The electronics industry also makes extensive use of stainless steel strips. The material is used in the production of connectors, contacts, and shielding components for electronic devices. Stainless steel’s resistance to corrosion, combined with its electrical conductivity, makes it an excellent choice for applications in computer hardware, mobile devices, and other consumer electronics.

5. Food Processing and Packaging

The food industry favors stainless steel strips for their hygienic properties and resistance to corrosion. These strips are used to manufacture equipment such as tanks, conveyors, and processing lines, ensuring that food products are not contaminated during processing. Moreover, stainless steel's smooth surface prevents bacteria build-up, making it easier to clean and sanitize.

6. Consumer Goods

Stainless steel strips are also found in everyday household appliances such as refrigerators, dishwashers, and ovens. The material’s resistance to heat, moisture, and chemicals makes it ideal for kitchen appliances and utensils. Beyond appliances, stainless steel strips are used in the manufacturing of items like razor blades, kitchen knives, and scissors, due to their sharpness and durability.

Jianglinsteel: Your Trusted Stainless Steel Strip Manufacturer

At Jianglinsteel, we pride ourselves on delivering precision-engineered stainless steel strips that meet international standards. Our products are available in various grades, including 201, 301, 304, 316, 410, and 430, catering to diverse industry requirements. We offer custom sizes and finishes to ensure that our clients receive products tailored to their specific needs.

Manufacturing Process

Our manufacturing process involves several key steps to ensure the production of high-quality stainless steel strips:

-

Raw Material Preparation and Smelting: Scrap steel and ferroalloys are melted in an electric arc furnace, followed by decarburization and composition adjustments.

-

Continuous Casting and Hot Rolling: The molten steel is cast into slabs and hot-rolled to enhance material uniformity.

-

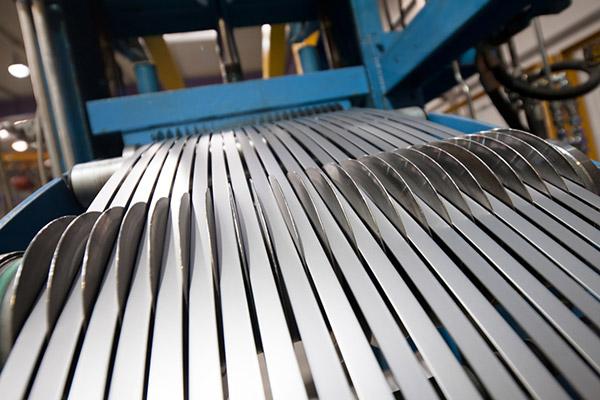

Cold Rolling: Hot-rolled strips are cold-rolled multiple times to achieve the desired thickness and flatness

-

Annealing and Pickling: Recrystallization annealing restores ductility, and pickling removes oxides, improving surface finish.

-

Slitting: Wide strips are cut into custom widths as per customer specifications.

-

Quality Control: Rigorous testing ensures compliance with international standards.

Why Choose Jianglinsteel?

-

Quality Assurance: We adhere to strict quality control measures to ensure the consistency and reliability of our products.

-

Customization: Our ability to provide custom sizes and finishes allows us to meet the unique requirements of our clients.