Precision and performance are the cornerstones of modern manufacturing. When it comes to producing high-tolerance, complex parts for aerospace, automotive, medical, or defense industries, CNC machining for specialty alloys stands as a trusted solution. Leveraging the latest in automated milling, turning, and multi-axis technologies, CNC machining delivers unmatched accuracy, consistency, and reliability for challenging materials.

Understanding Specialty Alloys in Modern Manufacturing

Specialty alloys are engineered metals designed to offer superior strength, resistance to corrosion, high-temperature endurance, or other performance characteristics not found in standard materials. Common specialty alloys include:

-

Inconel

-

Titanium alloys (e.g., Ti-6Al-4V)

-

Hastelloy

-

Monel

-

Duplex stainless steels

These materials are essential in high-performance industries due to their ability to retain structural integrity under extreme conditions. However, their unique properties make them notoriously difficult to machine using conventional techniques.

Why CNC Machining is Ideal for Specialty Alloys

Specialty alloys are tough, both literally and figuratively. Traditional machining techniques often fail to deliver the required precision or may lead to excessive tool wear, deformation, and overheating. CNC machining eliminates many of these issues through:

-

Precision Control: CNC machines follow pre-programmed CAD/CAM models with micrometer-level precision, ensuring every detail meets design tolerances.

-

Repeatability: Once the program is set, parts can be reproduced with exact consistency across short or long production runs.

-

Advanced Tooling: CNC machining uses coated carbide tools, coolant systems, and optimized feeds/speeds for working with hard-to-machine alloys.

-

Complex Geometry: 5-axis CNC machines allow for complex contours, undercuts, and intricate shapes often required in aerospace or medical components.

Applications of CNC Machining for Specialty Alloys

Aerospace Components

Aircraft and spacecraft components require lightweight materials that can withstand enormous stress and extreme temperatures. CNC machining enables the production of parts from titanium and Inconel alloys, such as:

-

Engine turbine blades

-

Structural brackets

-

Landing gear components

-

Satellite parts

Medical Implants and Devices

Biocompatibility and corrosion resistance are critical in medical applications. Titanium alloys are often machined into:

-

Bone screws and plates

-

Spinal implants

-

Surgical tools

Oil & Gas Equipment

In highly corrosive or high-pressure environments, materials like Hastelloy and duplex stainless steels are essential. CNC machining is used to manufacture:

-

Valve components

-

Sealing housings

-

Downhole tools

Automotive and Motorsport

High-performance automotive applications demand parts that can endure heat and stress. CNC machining allows manufacturers to work with specialty alloys for:

-

Exhaust manifolds

-

Turbocharger housings

-

High-strength suspension components

Challenges in CNC Machining of Specialty Alloys

Despite the advantages, machining specialty alloys is not without its difficulties. Manufacturers must navigate:

-

Tool Wear: Hard alloys can rapidly wear down cutting tools, increasing operational costs.

-

Heat Management: The generation of excessive heat can lead to workpiece distortion or tool failure.

-

Work Hardening: Some alloys become harder when machined, making them even more difficult to cut.

-

Surface Finish Requirements: High-precision industries often require flawless surface finishes, which demand careful process control.

Overcoming these challenges requires specialized expertise, the right tooling, and a strategic approach to machining parameters.

Choosing the Right CNC Machining Partner

Not all CNC shops are equipped to handle the complexities of machining specialty alloys. To ensure success, look for a machining partner that offers:

-

Experience with High-Performance Alloys: Prior knowledge of material behaviors and best practices is essential.

-

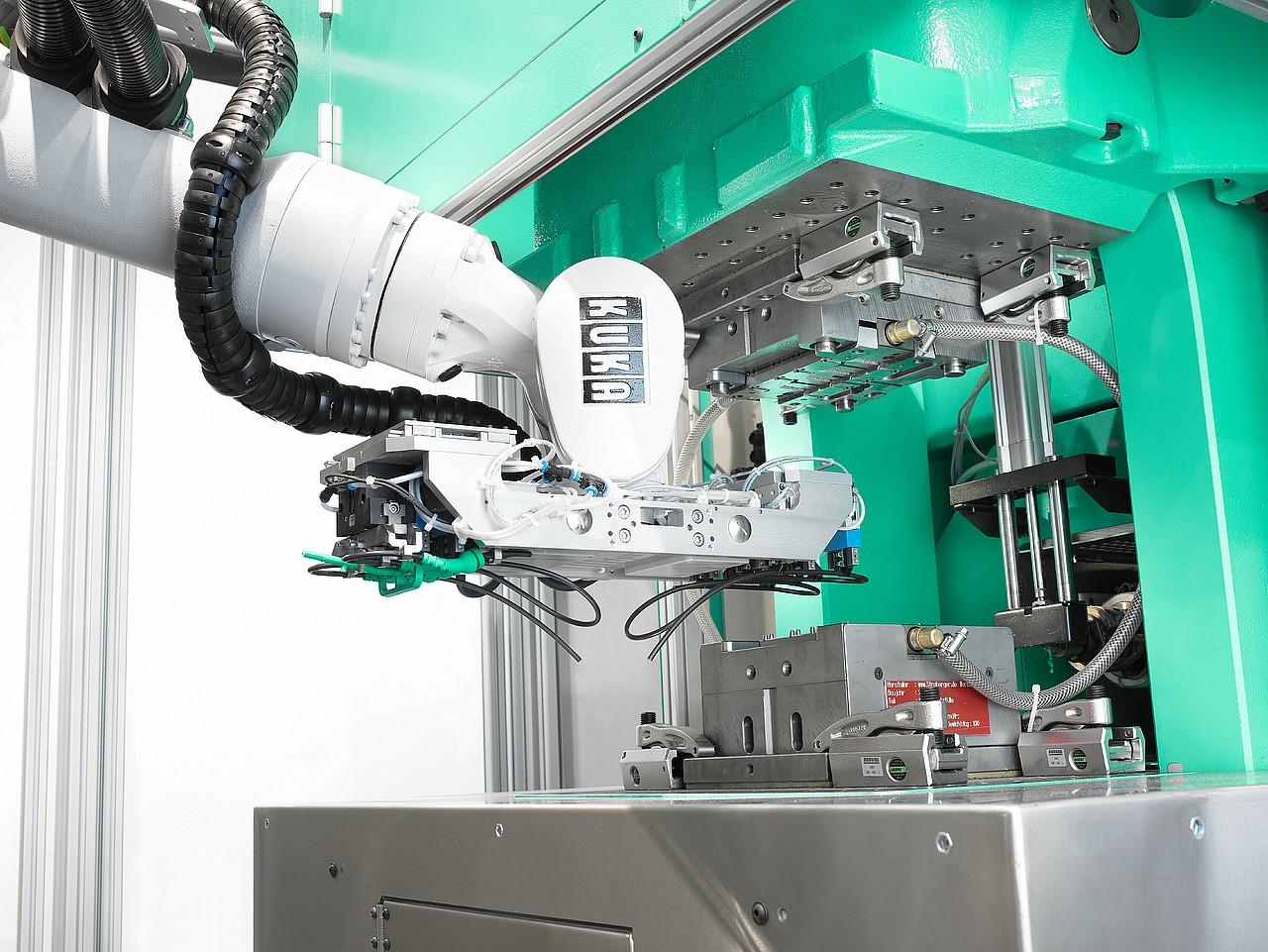

Advanced CNC Equipment: Multi-axis machines, high-rigidity setups, and real-time monitoring systems.

-

In-House Engineering Support: CAD/CAM programming, DFM (design for manufacturability) guidance, and prototyping capabilities.

-

Quality Assurance: ISO certifications, material traceability, and thorough inspection protocols.

At Elite Mold Tech, we specialize in CNC machining for specialty alloys with a proven track record across aerospace, medical, and energy sectors. Our commitment to precision, quality, and lead time efficiency makes us the trusted partner for clients worldwide.

The Future of CNC Machining with Advanced Materials

As engineering demands continue to push the envelope, the role of specialty alloys in manufacturing is only set to grow. Future developments in CNC machining will likely include:

-

Adaptive Machining Algorithms: AI-powered systems that adjust cutting parameters in real time.

-

Hybrid Manufacturing: Combining additive manufacturing with CNC machining for complex, high-performance parts.

-

Digital Twins: Virtual models that predict machining outcomes before physical production.

These innovations will make it even easier to achieve tight tolerances, reduce waste, and meet strict industry standards when working with challenging materials.

Conclusion

When precision, durability, and performance matter, CNC machining for specialty alloys is the go-to solution for manufacturers operating in demanding industries. By combining cutting-edge technology with expert craftsmanship, CNC machining unlocks the full potential of materials like titanium, Inconel, and Hastelloy. Whether you're developing aerospace components or medical implants, choosing a specialized CNC partner ensures your parts are produced to exact specifications—on time and within budget.